| Area | Upper Trinity |

| Topic | Tour: Trinity Lake Construction: Dam Photos |

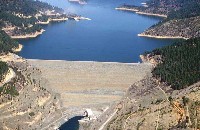

Photo of Trinity dam and full reservoir. Trinity lake has 16,000 surface acres, 145 miles of shoreline and a drainage area of 692 sq miles. The Trinity dam is a zoned earthfill structure 538 feet high and 40 feet wide at the crest. The crest is 2,600 feet long. The hydraulic height (head) is 440 ft with a normal water surface elevation of 2370 ft. Primary reservoir releases are made through the powerplant. At the time of final completion in 1961, Trinity stood as the highest embankment dam in the world until the California State Water Project's Oroville Dam, on the Feather River, superseded it. Photo and data courtesy of Bureau of Reclamation.

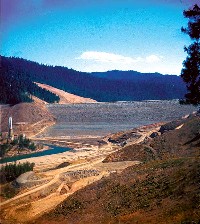

Photo showing up-river (lake) side of dam towards completion. Service spillway on top left of dam is still well above grade showing material is still to be added to dam top. Freestanding "glory hole" spillway that feeds the power house and controlled releases into the Trinity river is visible on left. Photo courtesy Sue Corrigan and family.

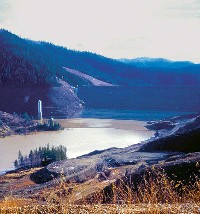

Photo showing up-river (lake) side of dam after completion and during partial fill state. Service spillway on top left of dam can now be seen below the dam crest (compare to previous photo). The service spillway allows for uncontrolled cresting of the lake during high inflow events, for example during a hundred year storm event. The Freestanding "glory hole" spillway that feeds the power house and controlled releases into the Trinity river is visible on left. Photo courtesy Sue Corrigan and family.

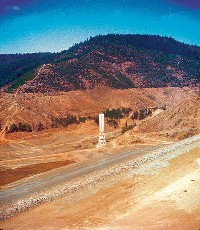

Photo taken from dam crest during construction showing freestanding "glory hole" spillway that feeds the power house and controlled releases into the Trinity river. Upper white section functions as a debris screen to protect the inlet. All primary reservoir releases are made through the powerplant. Papoose creek drainage runs off to the left (past glory hole). Photo courtesy Sue Corrigan and family.

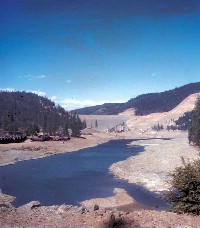

Photo showing downriver side of dam and a modified Trinity river channel. Photo is taken from what is now the bottom of Lewiston lake. Photo courtesy Sue Corrigan and family.

Photo showing construction of dam. Dam infill material was taken from what is now the location of the Trinity River Conservation Camp and was brought down to a staging site via a long conveyer belt. Rock riprap covered the upstream face of the dam were quarried form mine tailings brought up from what is now Lewiston lake. Partially assembled service spillway and outlet works can be seen above grade at the far end of the dam. Photo courtesy Sue Corrigan and family.

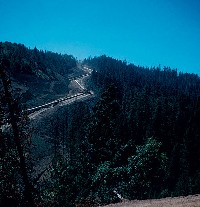

Photo showing conveyer belt that brought dam infill material from what is now the location of the Trinity River Conservation Camp (known than as the "barrow pits") to a staging site below. Trinity Dam's embankment consisted of four zones, or types, of materials; an impervious core material, a semi-impervious layer on either side of the core, river gravel, and rockfill. Rock riprap covered the upstream face of the dam. Riprap placement started in August 1959. The contractor used a two mile long conveyor belt to transport fill material from the borrow pit to the dam site. Use of the belt risked stoppage of the entire placement operation, should the belt machinery break down. The contractor decided to take the risk, as opposed to hauling the material by truck over steep grades. The conveyor transported an average of 20,000-25,000 cubic yards daily. Photo courtesy Sue Corrigan and family.

Photo showing silos, processing equipment and staging area at bottom of the conveyer belt. This belt brought down material for the dam infill from the barrow pits at what is now the Trinity River Conservation Camp. Photo courtesy Sue Corrigan and family.

Click on image to enlarge (62K).

Click on image to enlarge (62K). Click on image to enlarge (64K).

Click on image to enlarge (64K). Click on image to enlarge (52K).

Click on image to enlarge (52K). Click on image to enlarge (66K).

Click on image to enlarge (66K). Click on image to enlarge (35K).

Click on image to enlarge (35K). Click on image to enlarge (56K).

Click on image to enlarge (56K). Click on image to enlarge (101K).

Click on image to enlarge (101K). Click on image to enlarge (102K).

Click on image to enlarge (102K).

To learn more about this topic click Info Links

To view additional information (data source, aquisition date etc.) about this page, click Metadata

| www.krisweb.com |